AI Downtime Monitoring Solutions Cuts Microstoppages

THE PROBLEM

In many manufacturing environments, unplanned downtime isn’t just caused by major machine breakdowns. Instead, it’s often the accumulation of short, frequent microstoppages — small interruptions that last just a few seconds to a couple of minutes. These minor disruptions, caused by misfeeds, small jams, or brief operator delays, rarely get recorded or analysed because they seem insignificant in isolation. However, over time, they quietly erode production efficiency and contribute to major output losses.

Factory managers and supervisors may recognise overall line stoppages, but without the right AI downtime monitoring solutions, they lack the granular visibility to pinpoint when and why microstoppages occur. Traditional monitoring systems and manual reporting miss these short, frequent events, leaving teams blind to their real operational costs.

Challenges with Microstoppages:

- Invisible Production Losses: Small stops accumulate unnoticed, harming efficiency.

- Inadequate Downtime Reporting: Manual systems fail to track short disruptions accurately.

- Limited Root Cause Visibility: Teams struggle to identify and eliminate recurring minor issues.

THE SOLUTION

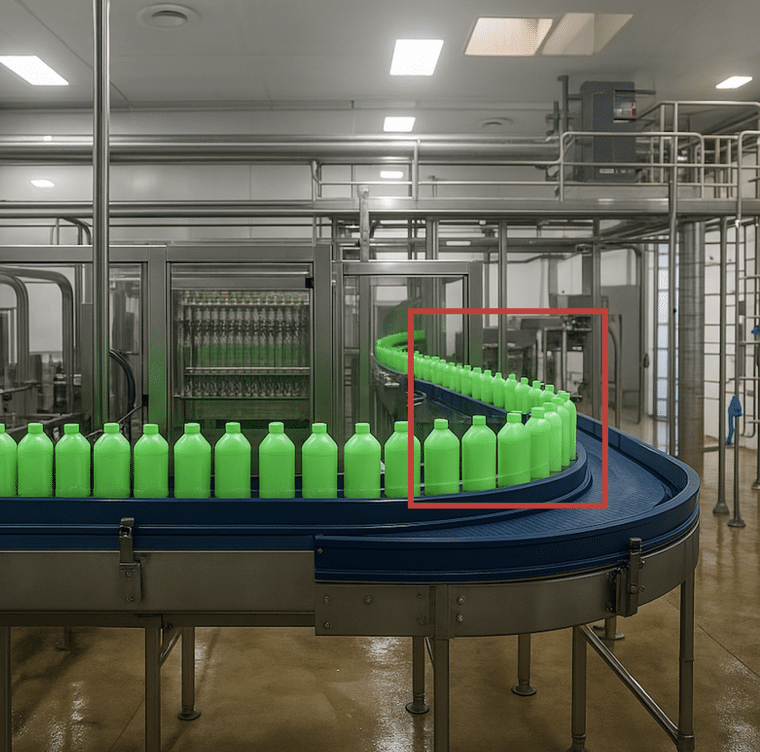

visionAI transforms downtime management by using existing CCTV infrastructure combined with advanced computer vision and AI. It continuously monitors key points on the production line, detecting even the shortest unplanned stops. visionAI automatically captures visual evidence, timestamps events, and categorises root causes, giving teams the clarity they need to respond effectively and eliminate recurring disruptions.

With visionAI, AI downtime monitoring solutions enable manufacturers to finally capture the true impact of microstoppages, understand what causes them, and implement targeted fixes — all without manual guesswork or expensive new hardware.

Benefits of Managing Microstoppages with visionAI:

- Real-time detection of even the shortest downtime events.

- Visual evidence and cause analysis for every microstop.

- Improved downtime reporting for better operational decisions.

- Continuous improvement leading to stronger OEE gains.

- visionAI turns small stops into big opportunities for efficiency gains.

The Result

With visionAI, manufacturers gained AI downtime monitoring solutions that revealed microstoppages previously invisible to traditional systems. Teams could finally see exactly when and why small stops occurred, supported by video evidence and root cause data. This allowed for faster interventions, smarter problem-solving, and targeted process improvements. Over time, manufacturers significantly reduced unplanned downtime, improved OEE, and increased overall production efficiency — all without needing to invest in new hardware or overhaul existing systems.

A 20% reduction in microstoppages has been shown to result in additional monthly revenue of $55,000, underscoring the financial impact of eliminating small, frequent inefficiencies with real-time insight.