Manual quality control is yesterday’s problem

Subjective

Manual quality control is often subject to the personal opinions and biases of the individuals performing the inspections, which can lead to inconsistencies

Human error

Manual quality control is prone to human error, including mistakes in judgment, misinterpretation of data, and simple oversight

Time-consuming

Manual quality control is a time-consuming process, especially for large-scale operations, which results in delays and increased costs

Expensive

Manual quality control is a costly process, requiring the hiring of additional staff, training, and equipment

Inefficient

Manual quality control requires a significant amount of time and resources to inspect each item or batch of products

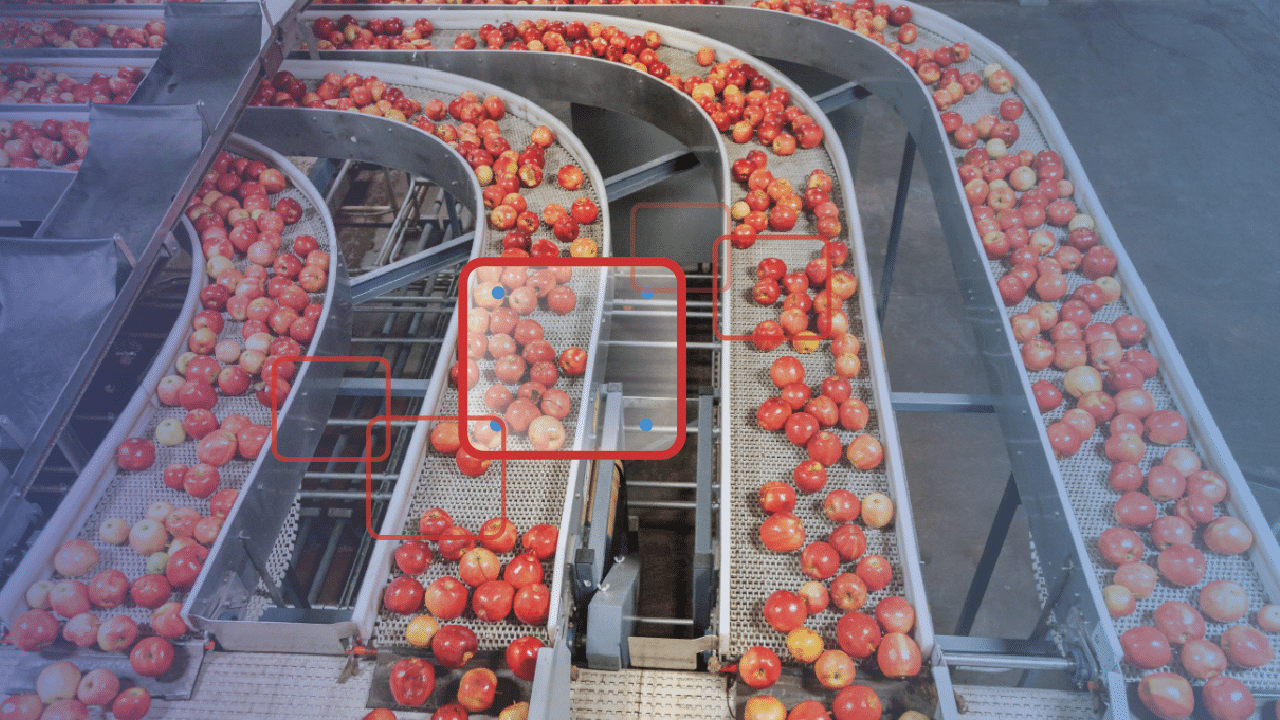

Computer Vision AI for Food Manufacturing

In the food manufacturing industry, quality control is everything.

But ensuring that quality control processes are carried out accurately and efficiently can be challenging. A reliance on manual processes can lead to inconsistencies in product quality, increased costs, and reduced efficiency. Computer Vision technology helps to overcome these challenges by providing a more objective, efficient, and accurate means of quality control.

visionAI for Food Manufacturing: Maximizing efficiency and reducing waste with AI-powered Computer Vision.

FOOD MANUFACTURING SOLUTIONS

How Computer Vision AI improves your business

Quality control

Sorting and grading

Packaging

Traceability

Transforming the food manufacturing industry through improved product quality and safety, reduced waste, and increased efficiency.

Food manufacturing solution features

- visionTrack features

- Additional features

Incident management and alerting

VisionTrack sends alerts when objects deviate from their expected location, status, or performance, enabling manufacturers to quickly identify and resolve issues in the production process. Vision Track detects incidents, such as product breakages, spills, or accidents, in real-time

Volume estimation

By analyzing the size and shape of products and materials, VisionTrack accurately estimates their overall volume. This information is useful for optimizing storage space, planning transportation, and improving the overall efficiency of the facility

Facial recognition

VisionTrack uses facial recognition to connect workflows to people on the production line. This feature enables manufacturers to identify and track workers, monitor their productivity, and ensure their safety

Quality control

VisionTrack detects multiple aspects of defects, errors, or anomalies in the manufacturing process, providing real-time feedback to operators

Quantity estimation

Vision Track's advanced algorithms accurately estimate the quantity of raw materials, components, and finished products in the facility

Object counting

VisionTrack counts multiple aspects of objects as they move through the manufacturing process

Object tracking

VisionTrack tracks multiple aspects of an object, component, or machine in real-time, providing updates on their location, status, and performance

- Administrative dashboards

- Liveness detection

- Document processing on your timelines

- Home affairs integration

- Robust queueing of people and items

- Improve the models with almost no input

- Full management from anywhere in the world

- Queue management built-in

- Remote monitoring and control

- Full API, event model, and sample code

- Differentiation between live people, images or tablets

- Processing within seconds

- Developer-friendly

- Easy verification and data enrichment

- Face recognition

- Advanced, human-parity* face recognition

Why visionAI for Food Manufacturing?

Versatile

Unlike traditional scanning technologies, which are often specialized and limited in their capabilities, VisionTrack uses computer vision to track, count, alert, and perform quality control tasks using any existing camera.

Cost-effective

VisionTrack eliminates the need for expensive hardware, such as specialized scanners, and can be implemented using any camera. It does not require data scientists to improve models and systems.

Speed of implementation

VisionTrack can be implemented and start adding value to a manufacturing operation in hours. In stark contrast to traditional scanning technologies, which often require significant time and resources to implement.

Empowered factory operators

VisionTrack is designed to empower factory operators by providing them with a tool that they can use themselves to train and improve the accuracy of the AI system.

Insights into the world of Computer Vision AI

As the fundamental technology that enables machines to “see” and interpret the world around them, Computer Vision is revolutionizing the value of business processes that involve objects, documents and people. The ability to automatically extract information from images, such as object recognition, scene reconstruction, and image segmentation opens up a world of endless possibilities.

Here are a few reasons why manufacturing companies choose visionAI:

Detecting Food Manufacturing Defects

Quality Control for Bread Manufacturing

Empower your factory operator to do more with less

Revolutionise your manufacturing processes with visionAI.

Leave your details and we’ll get back to you to discuss your needs.