Real-Time Bakery Equipment Monitoring for Industrial Bakeries

THE problem

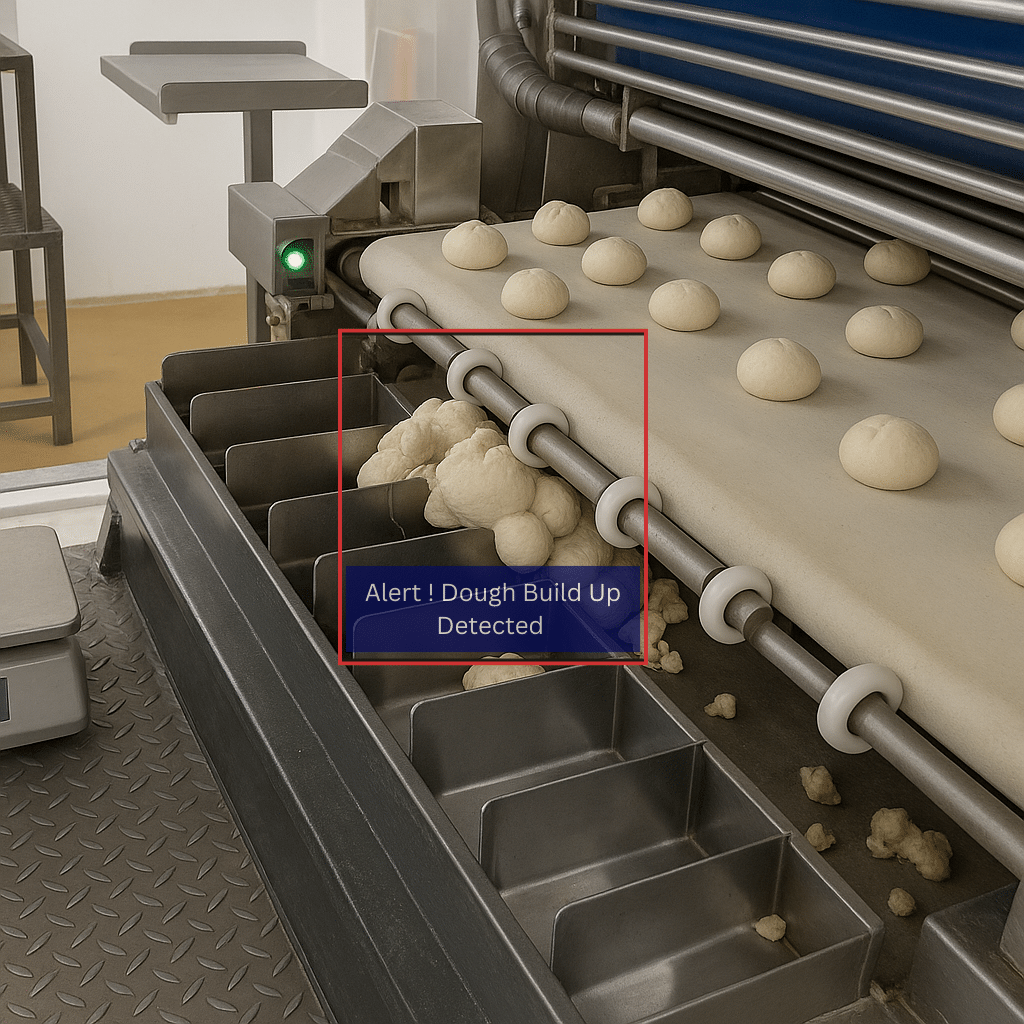

In high-speed industrial baking environments, real-time bakery equipment monitoring is crucial as dough build-up on critical machinery, especially around dough dividers and forming equipment, is a persistent operational risk. What starts as a small, almost invisible accumulation can quickly escalate into misaligned presses, inconsistent wraps, damaged flatbreads, or deformities in dough structure. Over time, this build-up increases mechanical strain, reduces machine stability, and creates product non-conformance that affects downstream processes.

Because the early signs of build-up are subtle and operator-dependent, they are often missed until the problem becomes severe. These blind spots have a direct impact on OEE:

- Availability declines when build-up triggers unplanned stoppages.

- Performance slows as machines struggle to run at optimal speed.

- Quality drops due to inconsistent dough handling, tearing, or poor shaping.

Traditional monitoring tools cannot detect these visual cues early enough. Without a real-time bakery equipment monitoring system, bakeries remain reactive, responding only after defects appear or equipment fails, resulting in downtime, waste, and costly corrective maintenance.

THE SOLUTION

visionAI delivers proactive oversight with its real-time bakery equipment monitoring system, transforming existing CCTV infrastructure into a continuous monitoring layer. Using advanced computer vision, the system detects early signs of dough build-up long before it disrupts production.

The AI monitors dough dividers, sheeters, and other critical points, identifying abnormalities operators may miss during routine checks. When potential build-up is detected, visionAI sends instant alerts so operators can intervene at the source, preventing escalation.

Key advantages include:

- Early detection of dough accumulation before it impacts quality or throughput.

- Instant operator alerts to avoid downtime and scrap.

- Reduced maintenance costs through proactive intervention.

- Improved OEE from stabilised equipment performance.

- Seamless deployment using existing camera systems

This approach adds the maintenance intelligence traditional sensors cannot measure.

The result

With a real-time bakery equipment monitoring system, bakeries detect problems earlier, maintain cleaner equipment, and prevent dough build-up from escalating into failures. Operators respond faster, reducing defects and maintaining consistent product quality. Over time, bakeries experience fewer stoppages, lower maintenance costs, and stronger overall performance.

Even a modest improvement has major financial impact: every 1% reduction in bread wastage saves $272,000 per year, making proactive maintenance one of the most valuable efficiency gains available. visionAI delivers this improvement without new hardware, just smarter insight into what’s already happening on the line.