Downtime Monitoring Solution Cuts Microstoppages in Food Production

THE PROBLEM

In most manufacturing environments, the biggest threat to productivity isn’t major breakdowns, it’s the accumulation of short, frequent microstoppages. These interruptions, lasting anywhere from a few seconds to a minute, are typically caused by minor jams, misfeeds, momentary operator delays, or unstable product flow. On their own, each microstop seems insignificant. However, across a full shift, these hidden losses erode OEE availability, slow performance, and introduce quality variation.

Because microstoppages are short and irregular, traditional downtime systems fail to detect or record them. Manual reporting is unreliable because operators often don’t notice stops under 30 seconds, and even when they do, they rarely log them. Without a downtime monitoring solution, these losses remain invisible, making it impossible for teams to understand true line performance or identify recurring inefficiencies.

This lack of granularity creates three major gaps:

- Invisible Production Losses: Microstoppages accumulate quietly, reducing output.

- Poor Downtime Reporting: Legacy systems miss short stops entirely.

- Limited Root-Cause Insight: Teams cannot diagnose what triggered the interruption.

Without this data, manufacturers remain reactive, fixing symptoms instead of eliminating the root causes behind frequent small stops.

THE SOLUTION

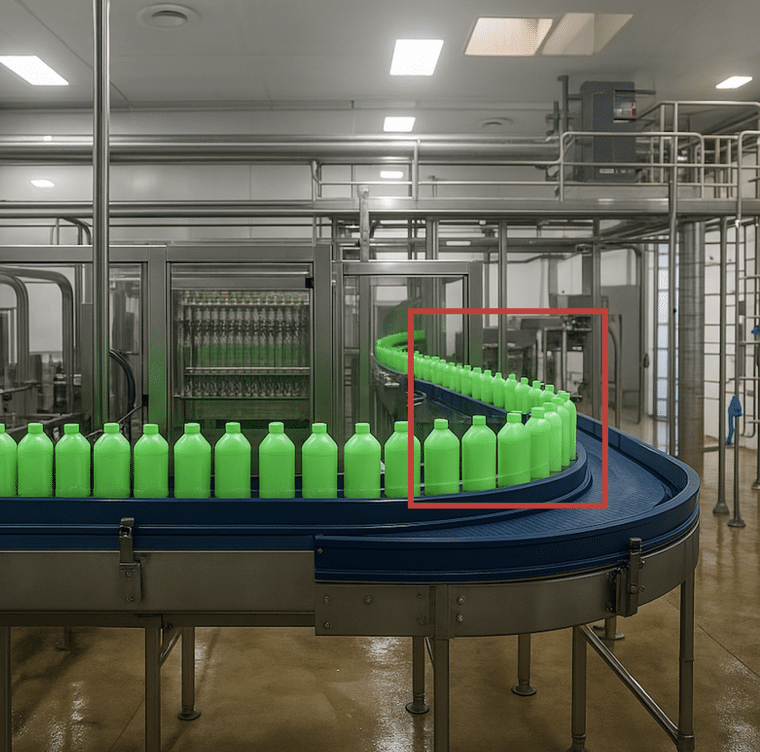

visionAI introduces real-time downtime monitoring solutions that transform existing CCTV cameras into a powerful visibility layer for microstoppage detection. Using computer vision, visionAI monitors key line locations continuously, identifying even the shortest unplanned stop with precise timestamps and visual evidence.

The system automatically:

- Detects microstoppages in real time

- Records video proof of each event

- Categorises root causes such as operator delay, product jam, misfeed, or upstream bottleneck

- Provides actionable insights for improving OEE

Because the solution requires no new hardware, manufacturers gain high-resolution downtime intelligence without disrupting operations.

The Result

With visionAI’s downtime monitoring solutions, manufacturers finally see the full landscape of downtime, not just major stoppages, but the hundreds of microstoppages that erode daily performance. Teams gain the insight needed to intervene faster, fix recurring issues, and stabilise production flow. Over time, factories reduce unplanned downtime, increase throughput, and improve OEE.

A 20% reduction in microstoppages generates approximately $55,000 in additional monthly revenue, demonstrating the significant financial impact of removing seemingly small inefficiencies with real-time AI visibility.