Efficient Bakery Production Line Eliminates Blind Spots and Boosts Performance

THE PROBLEM

Industrial baking production lines operate at extremely high speeds, but most bakeries only monitor one or two points in the process, usually around the oven or during packaging. This limited visibility creates large operational blind spots where product losses and performance issues occur unnoticed. These gaps directly impact OEE:

- Availability drops when micro-stoppages, jams, or pan misfeeds aren’t detected early.

- Performance suffers when conveyor flow slows or operators fall behind.

- Quality declines when skew pans, double dough balls, or open lids go unseen.

Many of these issues trace back to deeper root-cause factors such as operator inefficiency, misaligned equipment, inconsistent loading, or upstream process drift. Because teams cannot see where problems originate, they respond reactively, wasting valuable product, losing time hunting for the issue, and absorbing unnecessary downtime. Without an efficient bakery production line system, bakeries lack the real-time insight required to resolve issues before they escalate or to understand why recurring losses happen.

THE SOLUTION

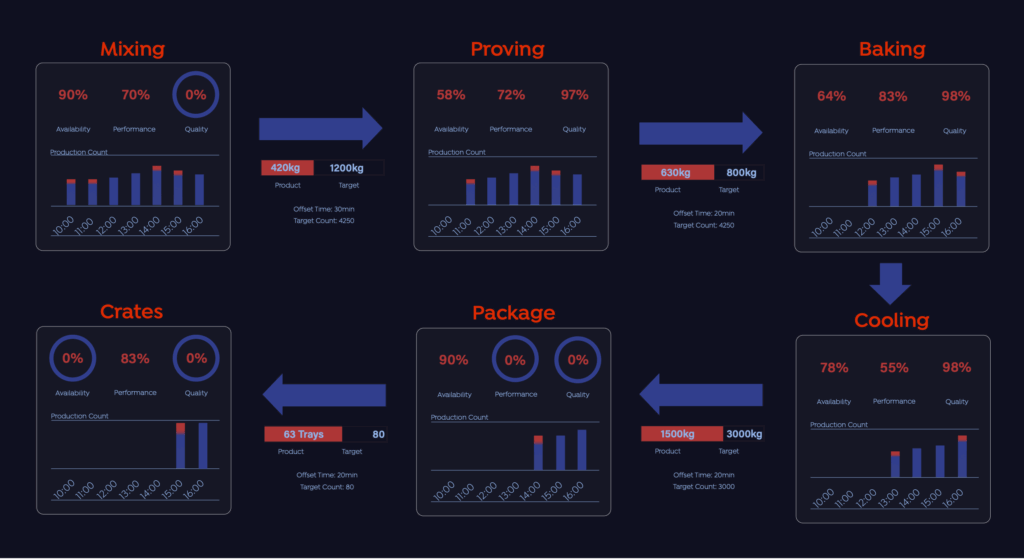

visionAI closes these visibility gaps by turning existing CCTV cameras into a continuous efficient bakery production line system that monitors every major stage of the line, from dough dividing and proving to baking, depanning, slicing, bagging, and crating. The AI provides real-time performance and quality monitoring, using camera-based analytics to detect skew pans, missing loaves, packaging delays, operator bottlenecks, and micro-stoppages.

The system:

- Detects Availability losses by flagging stoppages and jams instantly.

- Identifies Performance slowdowns caused by workflow delays or operator inefficiency.

- Highlights Quality deviations such as misaligned pans or incorrect dough placement

- Enables rapid root-cause analysis with visual evidence of where issues began

- Sends real-time alerts so teams can intervene before losses grow

No new hardware is required, bakeries simply unlock the intelligence already available in their camera infrastructure.

The Result

By implementing an efficient bakery production line system, bakeries eliminate blind spots and shift from reactive troubleshooting to proactive optimisation. Teams catch problems earlier, reduce waste, and improve consistency across shifts. Availability improves as micro-stoppages are addressed quickly, Performance stabilises with better operator oversight, and quality increases as defects are prevented upstream.

Bakeries using visionAI typically achieve up to a 5% improvement in OEE, equating to more than $1.3 million in annual financial impact, proving the power of full-line visibility and real-time efficiency intelligence.