Stamping out Cross-Contamination in Food Manufacturing

THE CHALLENGE

- In food manufacturing, cross-contamination and mispackaging, especially with allergenic ingredients, pose severe risks to consumer safety and the reputation of the brand.

- Tracking different ingredients through receiving, pre-batch, mixing and packing stages is complex.

THE SOLUTION

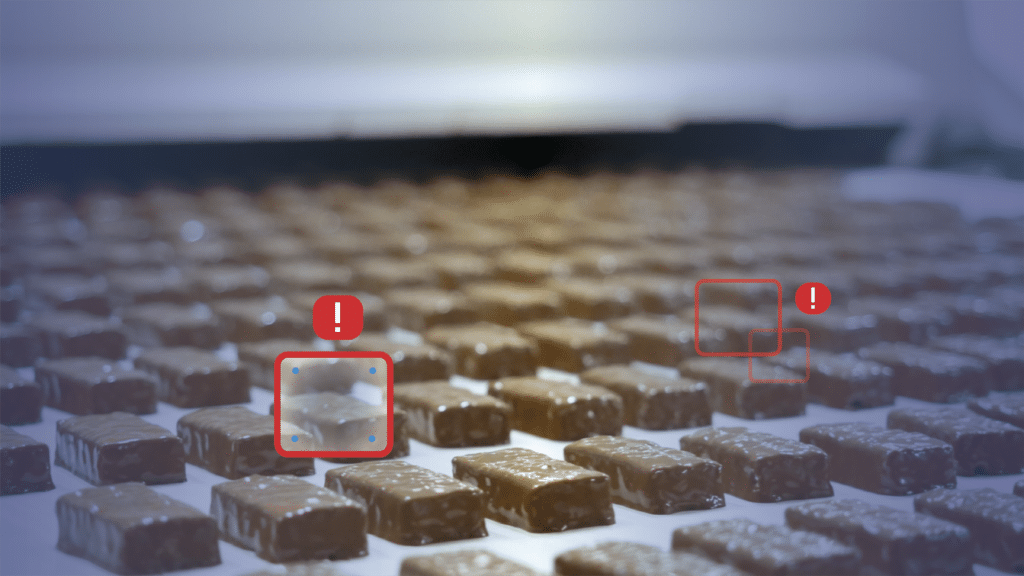

visionAI is designed to help manufacturers use any camera to passively monitor activities on the factory floor. By monitoring the movement of people and ingredients throughout the manufacturing process, it enables real-time tracking of risk areas, ensuring proactive prevention of cross-contamination.

THE RESULT

The AI tool offers a comprehensive view of the entire production process, enabling quicker identification and rectification of quality issues. This eliminates the need for manual checks at every stage of the process – facilitating a more compliant and efficient operation.