AI Baking Waste Control For Industrial Baking

Reduce waste, detect defects earlier, and optimise every baking batch with real-time AI Baking Waste Control using your existing CCTV system.

Smarter Industrial Baking Starts with Real-Time AI Baking Waste Control

In the world of high-speed, high-volume industrial baking, small errors can quickly spiral into large-scale losses. From skew pans and double dough to missed loaves and downtime, many of the most expensive issues are visual in nature — and often go undetected by traditional tools. Most baking lines rely on limited sensor data or manual processes that simply don’t deliver the full picture.

visionAI turns your existing CCTV infrastructure into a real-time AI monitoring solution for your bakery. With continuous visibility across every baking stage, our AI baking waste control system helps you detect and resolve problems before they escalate. Specifically built for operational teams in industrial baking, visionAI enables smarter decisions, better control, and measurable improvements in efficiency, quality, and compliance.

Discover How visionAI Improves Your Industrial Baking

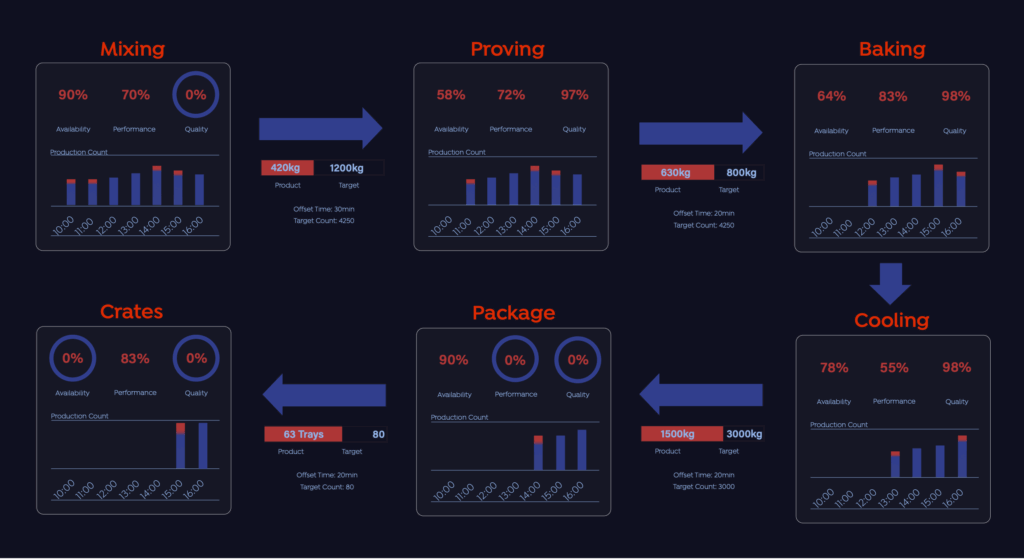

Real-Time OEE

Full Cycle (Dough to Crate)

Batch Flow Monitoring

Quality Incident Alerts

Waste/ Loss Transparency

Hygiene Control

How visionAI Works in Industrial Baking

visionAI integrates directly with your current camera infrastructure. Our platform applies AI to convert every CCTV feed into a smart visual monitoring tool. This enables AI Baking Waste Control across your entire line in real time.

Tracks critical stages: dough divider, prover, oven, depanner, slicer, bagger, and crating

Continuously measures loaf movement, pan status, production rhythm, and line interactions

Detects visual anomalies missed by traditional sensors and PLCs

Whether you’re tracking production flow, preventing waste, or improving efficiency, AI Baking Waste Control keeps your line visible and under control.

What You Gain from AI Baking Waste Control

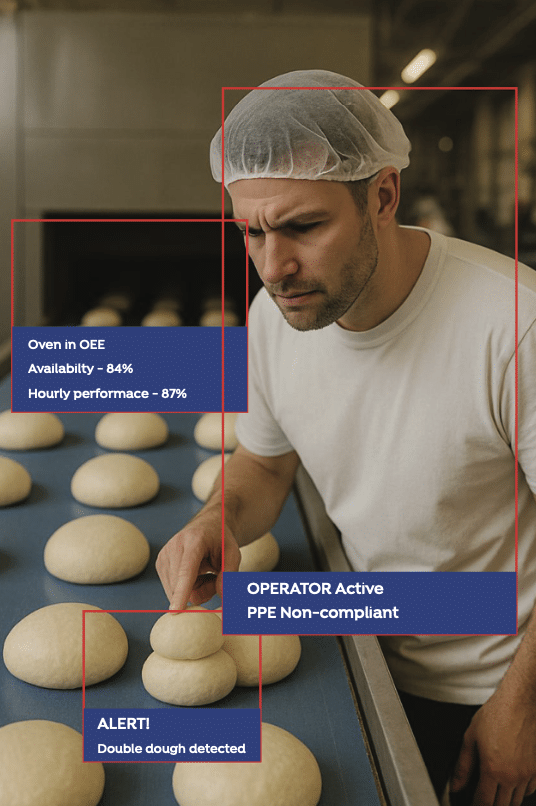

- Real-time detection of high-waste risks like skew pans and double dough.

- Immediate operator alerts when problems are visually identified.

- Shift-by-shift OEE dashboards powered by real-time camera feeds.

- SKU-specific production data and yield tracking.

- Reduction in operator error and unplanned downtime.

- Prevention of quality issues before they affect output.

- Visual records that enhance audits and training.

Results of AI-Driven Quality Control

- Every double dough incident avoided saves 6,500 bread loaves / 2-3 hours unplanned downtime / $4,750

- 5% efficiency improvement generates an additional $1,3m pa

- Every 1% reduction in bread wastage saves $272k pa

- Bread Stock losses reduced by 81%

- Skew pan incidents reduced by 93%

These results are possible with real-time AI Baking Waste Control.

Baking Problems Solved by AI Baking Waste Control

Double Dough, Skew Pans & Open Lids

These subtle but serious risks often result in burnt or rejected loaves. visionAI’s AI technology flags them in real time so operators can intervene immediately.

Excess Wastage & Yield Loss

Our AI tracks the entire flow — from dough input to packaged product — allowing teams to identify exactly where and why losses occur.

Short Stops & Downtime

With real-time camera monitoring, operators get instant alerts whenever flow slows or stops unexpectedly. These insights help reduce unplanned stoppages and improve OEE.

SKU-Level Visibility

visionAI recognises different product types on the line (e.g., white vs wholewheat, wrapped vs unwrapped) to give you accurate, batch-specific OEE and wastage metrics.

Manual Logging & Reporting

Ditch the clipboards and spreadsheets. visionAI captures and reports all key events automatically using AI-enabled cameras.

GMP & Hygiene Compliance

visionAI can monitor key behavioural indicators (KBIs) like handwashing, PPE use, and cleaning cycles to support food safety and audit readiness.

Transform Baking Operations From Reactive to Proactive

visionAI brings industrial baking operations out of the dark. By unlocking the full potential of your CCTV cameras through AI, bakeries gain powerful AI baking waste control capabilities to close critical visibility gaps, reduce wastage, and drive consistent OEE improvement.

Our system helps operators take real-time action — and gives managers the insights they need to understand performance trends and waste patterns over time. With visionAI, you can ensure each loaf is produced efficiently, safely, and to the highest standard.

How visionAI is Helping Industrial Baking

Explore our use cases to see how computer vision is empowering industrial bakeries like yours.

Bakery Line Product Monitoring with SKU Accuracy

AI Bakery Quality Control Prevents Skew Pan Losses

AI Camera Bakery Maintenance Control for Industrial Baking

AI Baking Line Efficiency Eliminating Blind Spots

Detecting and Alerting Food Manufacturing Defects

Quality Control for Bread Manufacturing

AI-Powered Baking Insight. Delivered Through Your Cameras.

Discover how visionAI’s AI Baking Waste Control is helping industrial bakeries reduce wastage, increase output, and unlock real-time production efficiency.